Wheel meet again...

...on Doc's wheel jig.

Hi all. Another quick workshop hint.

This is for those who make toys with wheels and need some way of finishing them and allowing them to dry.

I usually use Danish Oil to finish my wheels but this jig will work for hand or spray painted wheels too.

Sorry it is only another short posting, but it is close to christmas and in between making soap moulds, building and repairing spinning wheels and making all sorts of toys with wheels, I have not made the time to do a 'long' post here.

Rest assured I will as soon as I can. ![]()

In fact, I am hoping to put up a quick tutorial on soap making for those of you who have not made the jump into it yet, so stay tuned. ![]()

Wojaneed

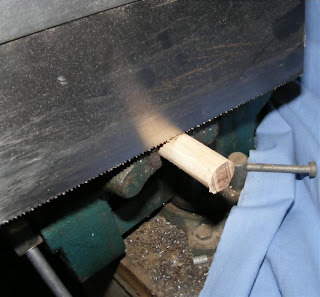

A couple of blocks of wood larger than the diameter of your wheels (otherwise the wheel will touch the ground - duhh)

Some thin dowel (3mm is good)

Flat space to 'finish' the wheels and leave to dry.

Step 1

Drill a hole into one block to fit the dowel into it.

Step 2

Finish/paint your wheels and thread them on to the dowel.

The end of the dowel that is not in the hole, will rest on the top of the block at the other end.

Need me to go over any of the steps?

Thought not. ![]()

Now if you will excuse me, I have work (fun though it is) to get on with.

Watch this space.

Love, peace and mungbeans

Doc ![]()